A skeletal robotic hand with working ligaments and tendons can now be 3D-printed in a single run. The creepy accomplishment was made doable by a brand new strategy to additive manufacturing that may print each inflexible and elastic supplies on the similar time in excessive decision.

The new work is the results of a collaboration between researchers on the ETH Zurich in Switzerland and a Massachusetts Institute of Technology spin-out known as Inkbit, based mostly in Medford, Mass.. The group has devised a brand new 3D inkjet printing approach able to utilizing a wider vary of supplies than earlier units.

In a brand new paper in Nature, the group has proven for the primary time that the expertise can be utilized to print complicated, transferring units product of a number of supplies in a single print job. These embody a bio-inspired robotic hand, a six-legged robotic with a grabber, and a pump modeled on the center.

“What was actually thrilling for us is that this expertise, for the primary time, allowed us to print full practical methods that work proper off the print mattress,” says Thomas Buchner, a PhD pupil at ETH Zurich and first writer of the paper describing the work.

The new approach operates on related rules to the sort of inkjet printer you may discover in an workplace. Instead of coloured inks although, the printer sprays out resins that harden when uncovered to ultra-violet (UV) gentle, and moderately than simply printing a single sheet, it builds up 3D objects layer by layer. It’s additionally able to printing at extraordinarily excessive decision, with voxels—the 3D equal of pixels–just some micrometers throughout.

3D Printed Robot Hand Has Working Tendonsyoutu.be

3D inkjet printers aren’t new, however the palette of supplies they will use has usually been restricted. That’s as a result of every layer inevitably has imperfections and the usual strategy to coping with this has been to scrape them off or roll them flat. This implies that tender or slow-curing supplies ci be used as they’ll get smeared or squashed.

Inkbit has been engaged on a workaround to this drawback for plenty of years. The firm has constructed a printer that includes a platform that strikes up and down beneath a number of inkjet items, a UV-curing unit and a scanning unit. After a layer has been deposited and cured, the scanner creates a depth map of the print floor, which is then in contrast towards the 3D mannequin to work out how one can modify the speed of deposition from the inkjet items to even out any irregularities. Areas that acquired an excessive amount of resin on the earlier layer obtain much less on the subsequent, and vice versa.

This means the printer doesn’t require any contact with the supplies as soon as they’ve been deposited, says Robert Katzschmann, a robotics professor at ETHZ who led the analysis. “That results in all types of advantages, as a result of now you should use chemistries that take longer to polymerize, that take longer to harden out, and that opens up an entire new area of rather more helpful supplies.”

“We can really now create a construction or a robotic in a single shot. It may require perhaps including a motor right here or there, however the precise complexity of the construction is all there.”

Previously, Inkbit had been utilizing a scanning strategy that might solely seize pictures of areas that had been two centimeters throughout at a time. This course of needed to be repeated a number of occasions earlier than all the pictures had been stitched collectively and analyzed, which considerably slowed down fabrication occasions. The new approach makes use of a a lot sooner laser scanning system—the gadget can now print 660 occasions sooner than earlier than. In addition, the staff has now demonstrated that they will print with elastic polymers known as thiol-enes. These supplies treatment slowly, however are a lot springier and extra sturdy than the rubber-like supplies often called acrylates which are usually utilized in business 3D inkjet printers.

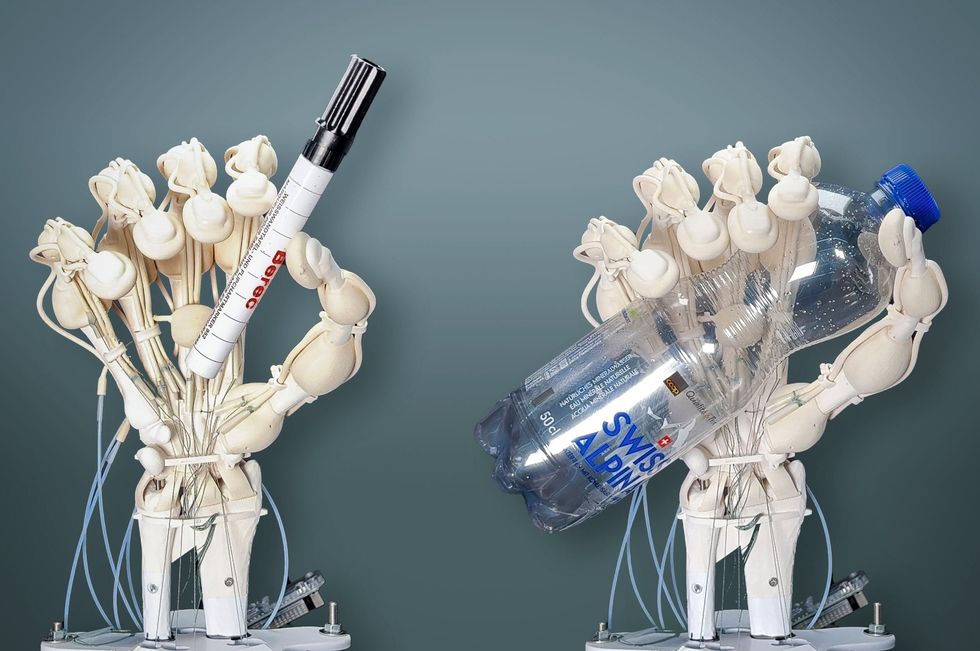

To reveal the potential of the brand new 3D printing course of, the researchers printed a robotic hand. The gadget options inflexible bones modeled on MRI scans of human arms and elastic tendons that may be linked to servos to curve the fingers in in the direction of the palm. Each fingertip additionally incorporates a skinny membrane with a small cavity behind, which is linked to a protracted tube printed into the construction of the finger. When the finger touches one thing, the cavity is compressed inflicting the strain contained in the tube to rise. This is picked up by a strain sensor on the finish of the tube, and this sign is used to inform the fingers to cease curling as soon as a sure strain has been reached.

The researchers used the hand to grip a wide range of objects, together with a pen and a water bottle, in addition to contact its thumb to every of its finger suggestions. Critically, all the practical elements of the robotic hand other than the servos and the strain sensors had been produced in a single printing job. “What we see as novel about our work is that we will really now create a construction or a robotic in a single shot,” says Katzschmann. “It may require perhaps including a motor right here or there, however the precise complexity of the construction is all there.”

The researchers additionally created a pneumatically powered six-legged robotic with a gripper that was capable of stroll backwards and forwards and choose up a field of Tic-Tacs, and a pump modeled on the center that featured a method valves and inside strain sensors that was able to pumping 2.3 liters of fluid a minute.

Future work will look to additional broaden the variety of supplies that the printer can use, says Katzschmann. They are restricted to supplies that may be cured utilizing UV gentle and that aren’t too viscous to work in an inkjet printer. But these might embody issues like laborious epoxies, hydrogels appropriate for tissue engineering and even conductive polymers that might make it doable to print digital circuits into units.